EP Epoxy Swimming Pool and Spa Paint Royal Blue 908132901 made by Ramuc

This premium low film build epoxy coating is formulated to provide ease of application and excellent coverage rates.

Ramuc EP Epoxy Swimming Pool and Spa Paint Royal Blue 908132901 facts:

- Protects previously painted epoxy or unpainted concrete/plaster/fiberglass/gelcoat swimming pools and spas

- Excellent choice for waterpark facilities, including slides

- High gloss, tile-like finish provides ease of cleaning

- Abrasion and chemical-resistant

- Self-priming

- Two-coat system

- VOC compliant everywhere in US and Canada

- Use SKID-TEX Additive to achieve a non-slip surface

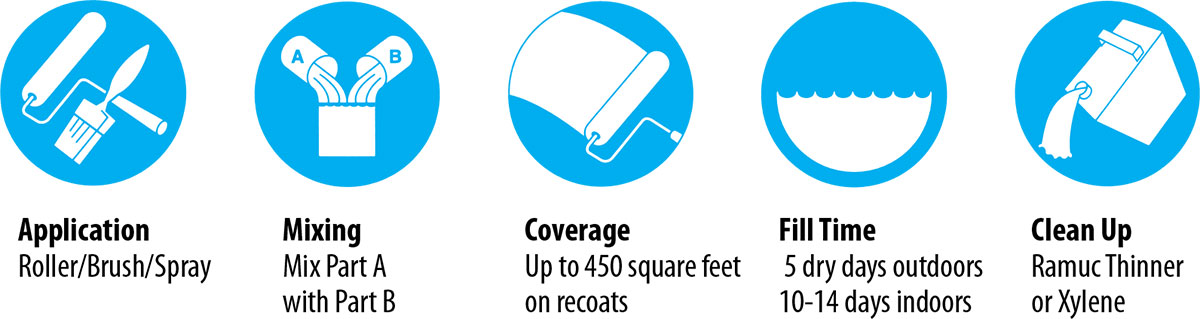

Ramuc EP Epoxy Swimming Pool and Spa Paint Royal Blue 908132901 Application:

- Roller

- Brush

- Spray

Ramuc EP Epoxy Swimming Pool and Spa Paint Royal Blue 908132901 Coverage:

- Up to 450 sq. ft./gallon on recoats

Ramuc EP Epoxy Swimming Pool and Spa Paint Royal Blue 908132901 Dry Time:

- Outdoor pool 5-7 Days to fill pool

- Indoor pool 10-14 Days to fill pool

- To Recoat: 12-72 Hours

Eight-hour ‘pot life’ when component A and B are mixed together

Ramuc EP Epoxy Swimming Pool and Spa Paint Royal Blue 908132901 Application Information:

Compatibility: For compatibility purposes, the existing paint on previously painted surfaces of a pool or spa should be determined before painting. Aged plaster should bechecked for integrity. Check for hollow or weak/crumbling plaster by using a ball-peen hammer or any other comparable method. Perform repairs on the plaster before painting.Use dark colors for accent painting only Dark colors can prematurely fade or blister, especially in chemically treated water.Joint and Crack filler: Plaster or concrete surfaces should be tested for integrity and soundness. Power wash the surface to remove loose paint and dirt. Should any minor repairsneed to be made, such as hydraulic cement patch or crack joint filling, do them at this time. We suggest using Vulkem polyurethane sealant. Do not use silicone-based products,as paint adhesion will be adversely affected. Vulkem must be top-coated before being submersed in chemically treated water. For compatibility purpose, the existing paint onpreviously painted surfaced of a pool or spa should be determined before painting. Aged plaster should be checked for integrity. Check for hollow or weak/crumbling plaster byusing a ball-peen hammer or any other comparable method. Perform repairs on the plaster before painting.Surface Preparation: Coating performance, in general, is proportional to the degree of surface preparation. Follow recommendations carefully, avoiding shortcuts. Inadequatepreparation of surfaces will virtually assure inadequate coating performance. We recommend using Clean and Prep Solution by Ramuc, the complete surface preparation productto clean and etch surfaces prior to painting. It takes the place of TSP/Etch/TSP. Use a 3500 p.s.i. minimum power washer. Follow package directions carefully.As an alternative, use Tri-sodium phosphate (TSP), Sulfamic or muriatic acid solution and high-pressure (3500 p.s.i.) minimum power washer. Scrub the entire pool surface withTSP solution to remove all dirt, oils and chalk. All surfaces should then be acid etched with 15-20% solution of sulfamic or muriatic acid to remove mineral deposits and to achieve amedium sandpaper grade finish on bare concrete or plaster surfaces. Neutralize/rinse with TSP and water. If surface is exceptionally hard, we recommend sanding with 60-80 gritsandpaper to create surface profile, prior to applying the first coat of EP.New concrete and plaster surfaces must be cured a minimum of 28 days prior to painting.Condensation Test: After all cleaning is completed, allow the pool surface to dry. Average dry times vary regionally and are dependent upon the porosity of the surface. It isrecommended to wait 5 dry sunny days then perform a condensation test to determine surface dryness.

- Tape 2’x2’ pieces of transparent plastic to areas in the deep end wall, floor and several of the other areas of the pool.

- Wait about 4 hours to determine if condensation has formed underneath the plastic.

- If condensation is evident, the surface is not dry enough to paint.

- Remove the plastic and wait 24 hours to perform the test again and continue until no condensation forms. This insures that the surface is dry enough to apply paint.

Application: Use no thicker than a 3/8′ nap roller used for solvent based paints. DO NOT use rollers with cardboard cores. Apply at the recommended coverage rate. Ideal airtemperatures for application are between 50deg. and 90deg. F. Surface temperature should be at least 50deg. F, no more than 90deg. F. Overnight curing temperatures must be at least 50deg. For the paint will not cure properly causing an ‘oily’ feel to the top of the paint. Do not paint when rain is imminent.Mixing the paint: EP Epoxy is self-priming; no other type of primer is recommended or should be used.

- Mechanically mix Part A for approximately 5 minutes

- Mechanically mix Part B for approximately 5 minutes

- Mechanically mix both part A and Part B together for approximately 15 minutes.

Mixing with a stir stick is not recommended. Type EP has a pot life (use life) of 8 hours.Once mixed allow the material to stand at 65º F and above for 30 minutes. Allow to stand at I hour at temperatures 50—65º to ensure chemical reaction before using. If material isused to soon after mixing or if pool is filled to soon after application yellowing or loss of gloss can occur. If more than one gallon kit is used at a time intermix several gallonstogether.Spray Information: Airless: 2000—2300 p.s.i. Tip Size: .0.33 -.0.43. Product should be thinned with Ramuc Thinner or xylene for proper atomization. Thin only up to state regulated VOC requirements.Coverage: 175—200 sq. ft. per gallon kit on bare, sand blasted or rough surfaces 400-450 sq. ft. per gallon kit on re-coats (Actual coverage will vary and is dependent upon the texture and profile of the surface.)Minimum dry film per coat: 1.7 mils dry (2..9 mils wet)Maximum dry film per coat : 2.0 mils dry (5.7 mils wet)Pot life— Use life: 8 hours @ 70º F and 50% relative humidityClean up: Ramuc Thinner or Xylenehttps://www.ramucpoolpaint.com/(800) 745-6756

Reviews

There are no reviews yet.